About Doug Turner Atlanta Custom Furniture Maker

- ABOUT -

DOUG TURNER

FURNITURE DESIGNER & BUILDER

About Doug Turner Atlanta Custom Furniture Maker

- ABOUT -

DOUG TURNER

FURNITURE DESIGNER & BUILDER

Doug Turner

I started building furniture around 1996, while I was a student at The Atlanta College of Art. We were given a woodworking intro class so that we could build canvas stretchers and frames instead of buying them. I found that I loved woodworking, and used the school shop a lot after that lesson. I worked on simple projects I could teach myself to build until I went to visit my uncle in New Jersey. At the time, he owned a custom furniture & millwork shop. He's a pretty blunt guy. He told me to quit playing around. If I really wanted to learn, I'd need to get a job in a real shop. I returned to Georgia, graduated from college and went to work in a high-end furniture shop here in Atlanta, which is now closed. It was an interesting experience - I learned as much about what not to do as what to do. The quality of the furniture we produced was very high, but the business administration was, awful if I'm being honest. In progress. I am very busy making furniture.

Video

- FURNITURE MAKING -

VIDEOS

Video

- FURNITURE MAKING -

VIDEOS

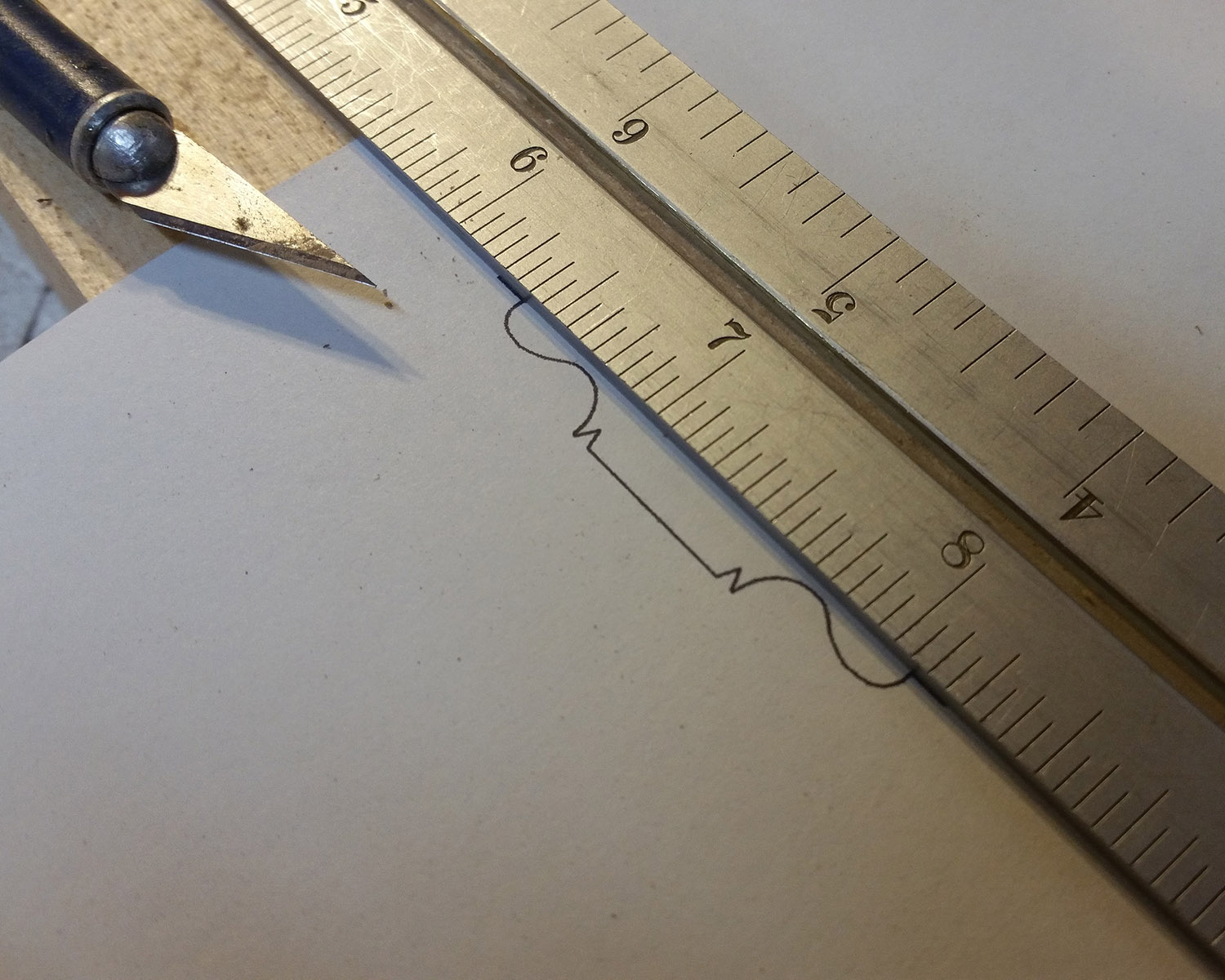

I'm using a pattern sander to create a sabre leg. The image below shows the completed desk. I made the video as a review of the sanding drum, which is not perfect but works well. I've edited out the boring parts here.

I'm applying a coat of wax to a walnut dining table.

I'm resawing some 2" thick x 10' long walnut to reduce the amount I'll have to remove in the surface planer. I'll make two passes per sides. As this piece is about 7" wide, I won't be able to get all the way through, but I'll be close. I'll simply snap off the waste and run it through the planer.

It's important to mask-off areas of furniture as you sand, to avoid cross grain scratches, which are a nightmare to remove if they occur.

Glazing adds depth to a finish by adding "low-lights" to corners and crevices. First I stained the cabinet, then sealed it with a few coats of shellac. After a light sanding, I applied a coat of glaze. I brushed it on, then wiped it off, leaving it in the crevices. After it dries, I'll shellac the piece again, sand, then add a few coats of wipe-on poly.

The final step in finishing a piece is waxing. I use 0000 steel wool and liquid wax, gently buffing the finish. I'll remove the excess wax with a clean rag after I've finished the entire cabinet (not shown, I can only ask so much of you, dear viewer).

Here, I'm cutting a mortise for a hinge, in black and white no less.

Tapering a leg for a walnut and ash dresser. The throat plate has been removed, because the little wedges kept getting jammed between it and the blade.

Blog Index

- TURNER CUSTOM FURNITURE -

BLOG

Blog Index

- TURNER CUSTOM FURNITURE -

BLOG